Case Study Overview

Objective

This activity aims to equip students with the practical skills required to assess, identify, and manage risks in construction environments. Through a detailed, hands-on approach, students will learn to evaluate workplace hazards, calculate exposure risks, and propose control measures to ensure a safer and healthier work environment. The task will cover essential aspects of risk management, including manual handling, noise, heat exposure, and fall prevention, helping students apply theoretical concepts in real-world scenarios. By completing this activity, students will strengthen their ability to recognize potential dangers and act effectively to reduce risks in the construction industry.

Challenge

Implementing comprehensive fall protection across 4 simultaneous construction phases while maintaining productivity targets. The solution required balancing NR-18 compliance for 12 elevated work zones, retrofitting 5 aging concrete mixers to meet NHO-06 noise/heat limits, and achieving 95% workforce adoption of new ergonomic protocols. Critical hurdles included coordinating guardrail installations during tight schedules, mitigating 102dB(A) equipment noise without production delays, and maintaining WBGT < 32°C for non-acclimatized workers during peak summer operations. Success depended on integrating technical controls with behavioral safety practices across 150+ workers while adhering to < R$1.2M safety budget constraints.

Introduction

We are now starting the M.A.P.A. activity for the Ergonomics and Occupational Safety course. Get ready to put into practice the concepts studied during the course!

Our activity is titled "Risk Management in Civil Construction." In this activity, we will explore the importance of risk management in the context of occupational safety, providing a practical opportunity to apply the knowledge acquired about risk management, occupational hygiene, ergonomics, and occupational safety in civil construction.

In the civil construction sector, where the complexity and diversity of risks are inherent, effective risk mapping is essential to ensure the safety and well-being of workers involved in each stage of the process. Through this activity, we aim to develop your analytical skills and ability to identify, evaluate, and propose appropriate control measures for the risks present in this work environment.

To develop these skills, the M.A.P.A. activity is divided into four stages, each with specific objectives:

Stage 1: Risk Identification in Civil Construction

In this stage, you will create a checklist based on the items of NR-18, apply this checklist to a work situation, build a flowchart of the civil construction process to identify risks, and finally, prepare a summary table of the risks found. This stage will allow a deep understanding of the risks related to the various stages of the construction process.

Stage 2: Manual Handling of Loads

In this stage, you will analyze manual load handling and identify errors and unsafe practices, creating a summary table of the risks associated with this activity. The goal is to enhance your ability to identify specific risks in a common task in civil construction.

Stage 3: Noise and Heat

In this stage, you will calculate the noise dose based on intensity and exposure time, and calculate the WBGT (Wet Bulb Globe Temperature) based on temperature, activity, and heat. This stage will develop your ability to assess risks related to these specific occupational agents.

Stage 4: Risk Analysis and Control Measures

In this final stage, you will define probabilities, severities, and risk levels for the risks identified earlier. Additionally, you will propose appropriate control measures and prioritize the risks. This stage will consolidate your ability to analyze and propose practical solutions for the identified risks.

Context

You have been hired as an occupational safety consultant for a civil

construction company. Your mission is to identify and analyze the

risks present in their construction sites to propose efficient

control measures to ensure worker safety. To achieve this, you will

carry out an activity divided into four stages, using the knowledge

acquired about risk management, occupational hygiene, ergonomics,

and occupational safety in civil construction.

By completing this activity, you will be better prepared to face the challenges of occupational safety in civil construction, as you will have applied theoretical concepts to a practical situation.

We hope you take advantage of this opportunity to enhance your skills and knowledge, recognizing the fundamental importance of risk management in the work environment context.

Stage 1

In this stage, you will identify risks at the construction site. You will create a safety inspection checklist for fall prevention measures and a flowchart of the production process at the site to map the risks. Then, you will apply the checklist, evaluating the situation in the following figure.

To create the checklist, first, access the text of Regulatory Standard NR-18 (available at: NR-18). You will build the checklist based on items 18.9.1 to 18.9.4.4.7.

Answer the following items:

1.a) Create a checklist based on items 18.9.1 to 18.9.4.2 of Regulatory Standard No. 18 for risk identification at a construction site. The checklist will be used in a safety inspection of fall prevention measures at height. Minimum of 5 items.

| ITEM | YES | NO | N/A | NOTES |

|---|---|---|---|---|

| Existence of protective screens between open gaps | ||||

| Does the top rail of the guardrail have a height greater than 1.2m? | ||||

| Does the intermediate rail of the guardrail have a height of 0.7m? | ||||

| Does the skirting board have a minimum height of 0.15m flush with the surface? | ||||

| Are there temporary covers for floor openings? |

1.b) Apply the checklist to the construction site situation presented in Figure 1. Record the identified risks and make relevant notes. Minimum of 5 items.

Date: 17 September 2023

Responsible: Rafael Queiroz

| ITEM | YES | NO | N/A | NOTES |

|---|---|---|---|---|

| Existence of protective screens between open gaps | X | No protective screen exists | ||

| Does the top rail of the guardrail have a height greater than 1.2m? | X | Guardrail does not exist | ||

| Does the intermediate rail of the guardrail have a height of 0.7m? | X | Guardrail does not exist | ||

| Does the skirting board have a minimum height of 0.15m flush with the surface? | X | Guardrail does not exist | ||

| Are there temporary covers for floor openings? | X | No floor openings exist |

1.c) Build a flowchart of the civil construction process, from start to completion of the project. Use symbols or arrows to represent the stages and connections of the process.

1.d) Identify the risks present in each stage of the flowchart. Prepare a summary table highlighting the risks found, including the risk description and the process stage where it occurs. Minimum of 5 items.

| RISK | PROCESS STAGE | RISK DESCRIPTION |

|---|---|---|

| 1 | Excavation, foundation, and rock removal | Risk of workers entrapment, especially in the initial stages. |

| 2 | Preparation of steel structures | The process of constructing metal structures involves manual work, and if ergonomic factors are not observed, it can cause health issues for workers due to long periods performing these activities. |

| 3 | Preparation of concrete structures | Workers are often exposed to sunlight for long periods. |

| 4 | Roofing and covering | Risk of workers falling, as the work is performed at high elevations. |

| 5 | Finishing | Exposure to harmful chemicals, as workers may come into contact with toxic substances during the finishing process. |

Stage 2

Observe the following Figure 2, which illustrates a routine activity in the civil construction industry.

Considering the situation presented, identify possible errors or unsafe practices related to load handling.

Answer the following items:

2.a) Is the load handling work static or dynamic? Explain your answer based on the concepts learned.

Load handling involves a series of actions, such as pulling, pushing, dragging, lifting, lowering, and holding objects, using body strength, as highlighted by Silva (2019).

To answer the question, it is necessary to understand the concepts of static and dynamic work, as explained by Silva (2019) in Unit 5:

Static work is characterised by sustained muscle contraction over long periods, such as when holding a load, for example, a bag of cement. During this activity, the arm muscles remain contracted, which is a typical characteristic of static movement.

On the other hand, dynamic work involves body movement. This occurs when bending down to pick up or deposit a load or when walking while carrying it. These actions are representative of dynamic movement during load handling.

Thus, load handling is an activity that encompasses both static and dynamic work, and this distinction is relevant for understanding the risks involved in occupational safety.

2.b) What are the main applicable guidelines for load handling?

According to Silva (2019), the main recommendations for load handling are:

- Keep the back straight and knees bent when holding and lifting loads.

- Keep the load as close to the body as possible and, when possible, between the knees with a good foot position.

- Keep the load grip height above the knees.

- Secure straps and ropes on loads that do not have a satisfactory grip.

- Avoid twisting the torso when lifting or lowering a load.

- Prefer pushing or pulling loads instead of lifting and lowering them.

- Always try to use mechanical aids for load handling.

Additionally, there are recommendations regarding the maximum load a person can carry, which varies according to age and gender.

Stage 3

In the activities of a concrete mixer operator—a worker who operates the concrete mixer for cement production—exposure to noise and heat was observed.

The sources of noise are the concrete mixer equipment itself and the noise from other equipment used nearby. The heat comes from the sun, as, despite the covered area, in the afternoon, there is direct sunlight on the worker's body.

In the noise assessment, the following sound pressure levels were observed:

| Sound Intensity | Exposure Time |

|---|---|

| 88 dB(A) | 2 h |

| 86 dB(A) | 5 h |

| 74 dB(A) | 1 h |

In the heat exposure assessment, the following data were found:

- Natural Wet Bulb Temperature = 29.2 °C

- Globe Temperature = 41.3 °C

- Dry Bulb Temperature = 33.1 °C

To perform their activities at the concrete mixer, in a 60-minute cycle of worst exposure, the worker performs the following tasks:

- Carries cement bags to the concrete mixer and uses hands and arms to rotate the drum. Duration: 40 min.

- Waits beside the concrete mixer to prepare the mixture, performing moderate handwork: 20 min.

- The worker performing the activity is considered non-acclimatized.

Based on the above information, answer the following items:

3.a) What is the noise exposure dose value based on the tolerance limits of NR-15?

The noise exposure levels presented are: 88dB for 2h, 86dB for 5h, and 74dB for 1h.

According to NR-15 (2023), the tolerance limits for these noise levels are: 88dB for 5h and 86dB for 7h. For the 74dB period, there is no recommendation in the standard's table, but since the worker is exposed to it for only 1 hour and it does not reach the minimum limit of 85dB established by the standard, it will not be considered.

Applying the formula provided in the standard:

\( D = \frac{C1}{T1} + \frac{C2}{T2} + \frac{C3}{T3} \)

\( D = \frac{2}{5} + \frac{5}{7} + 0 \)

\( D = \frac{14 + 25}{35} \)

\( D \approx 1.1143 \)

Thus, the noise exposure level exceeds the tolerance limit of 1 established by the standard.

3.b) What is the WBGT value, considering the tolerance limits established by NHO-06?

Data:

- Natural Wet Bulb Temperature = 29.2 °C

- Globe Temperature = 41.3 °C

- Dry Bulb Temperature = 33.1 °C

Considering the presence of solar load, the following formula is used to calculate WBGT:

\( WBGT = 0.7 \cdot tbn + 0.2 \cdot tg + 0.1 \cdot ts \)

Thus:

\( WBGT = (0.7 \cdot 29.2) + (0.2 \cdot 41.3) + (0.1 \cdot 33.1) \)

\( WBGT = 20.44 + 8.26 + 3.31 \)

\( WBGT = 32.01 \, \text{°C} \)

3.c) What is the average metabolic rate of the activity in the 60-minute cycle, considering the tolerance limits established by NHO-06? Justify.

Data:

- Carries cement bags to the concrete mixer and uses hands and arms to rotate the drum. Duration: 40 min.

- Waits beside the concrete mixer to prepare the mixture, performing moderate handwork: 20 min.

According to NHO-06, the metabolic rate is tabulated according to the activity performed:

| Activity | Metabolic Rate (W) | Duration (min) |

|---|---|---|

| Standing, squatting, or kneeling. Heavy work lifting, pushing, or dragging weights (e.g., shovelling, trenching) | 524 | 40 |

| Moderate handwork | 180 | 20 |

Applying the data to the formula:

\( M = \frac{(Mt \cdot Tt) + (Md \cdot Td)}{60} \)

\( M = \frac{(524 \cdot 40) + (180 \cdot 20)}{60} \)

\( M = \frac{20960 + 3600}{60} \)

\( M = 409.333 \, \text{W} \)

3.d) Based on the calculated metabolic rate and WBGT values, verify if the tolerance limit, given by NHO-06, has been exceeded. Justify your answer.

Data:

- WBGT: 32.01°C

- Metabolic Rate: 409.333 W

According to the NHO-06 table, for a WBGT of 32.1°C, the maximum allowed metabolic rate is 137 W, which is much lower than the observed result. Therefore, the metabolic rate limit was not respected, and the tolerance limit was exceeded.

Stage 4

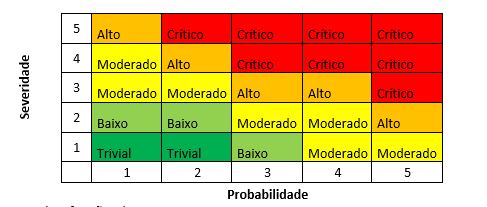

In this stage, you will analyze the degree of each risk identified earlier. For this, use the following severity, probability, risk, and prioritization gradation data.

For risk agents without a defined tolerance limit, the following severity gradation scale is adopted:

| Value | Meaning |

|---|---|

| 1 | Insignificant: causes discomfort or dissatisfaction, no medical treatment required. |

| 2 | Minor: temporary disability requiring medical treatment. |

| 3 | Moderate: partial permanent disability. |

| 4 | Major: death, total disability (>30%) up to 10 people. |

| 5 | Catastrophic: multiple deaths or total permanent disability for more than 10 people. |

For risk agents with a defined tolerance limit, the following severity gradation scale is adopted:

| Value | Meaning |

|---|---|

| 1 | Minor injuries requiring no medical attention, discomfort, or malaise. |

| 2 | Serious reversible injury or illness. |

| 3 | Critical irreversible injury or illness that may limit functional capacity. |

| 4 | Disabling or fatal injury or illness. |

| 5 | Multiple deaths or disabilities. |

For risk agents without a defined tolerance limit, the following probability gradation scale is adopted:

| Value | Meaning |

|---|---|

| 1 | Represents the best available control technology or practice. |

| 2 | Control following legal standards, adequately maintained. |

| 3 | Adequate control with minor deficiencies in operation or maintenance. |

| 4 | Incomplete control or with significant deficiencies. |

| 5 | Control measures are nonexistent or entirely inadequate. |

For risk agents with a defined tolerance limit, the following probability gradation scale is adopted:

| Value | Meaning |

|---|---|

| 1 | Exposures < 10% LEO. |

| 2 | Exposures >10% and < 50% LEO. |

| 3 | Exposures > 50% and < 100% LEO. |

| 4 | Exposures > 100% to 500% LEO. |

| 5 | Exposures exceeding 5 x LEO. |

The risk classification is given by the combination of probability and severity values. The obtained value can fall into the following risk classes and prioritization:

Source: the Author (2023).

| Category | Actions |

|---|---|

| Trivial | No action or record required. |

| Low | Maintain risk level and arbitrary monitoring. |

| Moderate | Implement control measures on a defined schedule and reduce risk; mandatory monitoring. |

| High | Implement urgent control measures and reduce risk. Reassess risk. |

| Critical | Stop activity or perform immediate intervention. Reassess risk. |

Answer the following items:

4.a) Define the probability of occurrence for the risks identified in the previous stages. Justify your choice based on the severity of the risk and the present conditions. Minimum of 5 items.

| RISK | PROBABILITY | JUSTIFICATION |

|---|---|---|

| Entrapment | 2 | Risk of entrapment exists during excavation and foundation, but applying prevention measures reduces the probability. |

| Ergonomic Risk | 2 | Risk due to the steel structure fabrication process. It can be considered a mild risk. |

| Prolonged Sun Exposure | 3 | Risk associated with concrete pouring. As it is a long phase where workers are continuously exposed to the sun, its probability is significant. |

| Fall Risk | 4 | Risk arising from roof installation. Workers operate at high elevations, and safety elements like protective screens and guardrails are not always present, making this risk significant. |

| Exposure to Chemicals | 2 | Risk present during the finishing phase. Following legal standards and proper use of PPE reduces the probability. |

4.b) Define the severity of the identified risks. Justify your choice considering the potential consequences for workers and the company. Minimum of 5 items.

| RISK | SEVERITY | JUSTIFICATION |

|---|---|---|

| Entrapment | 5 | The severity of entrapment risk is high, as it can result in fatalities and involve multiple people. |

| Ergonomic Risk | 2 | The severity of this risk is mild, potentially causing reversible injuries with appropriate medical treatment. |

| Prolonged Sun Exposure | 2 | The score is justified by the risk of reversible skin diseases due to solar radiation. |

| Fall Risk | 5 | The severity of this risk is high, as it can result in disabling or fatal injuries. |

| Exposure to Chemicals | 4 | The score of 4 is assigned due to the potential for fatal exposure to toxic agents. |

4.c) Determine the risk level for each identified risk by combining the probability of occurrence and severity. Classify the risk as low, medium, or high. Minimum of 5 items.

| RISK | SEVERITY X PROBABILITY | JUSTIFICATION |

|---|---|---|

| Entrapment | Critical | Probability: 2 Severity: 5 |

| Ergonomic Risk | Low | Probability: 2 Severity: 2 |

| Prolonged Sun Exposure | Moderate | Probability: 3 Severity: 2 |

| Fall Risk | Critical | Probability: 4 Severity: 5 |

| Exposure to Chemicals | High | Probability: 2 Severity: 4 |

4.d) For each identified risk, propose appropriate control measures, considering prevention principles and safety best practices. Minimum of 5 items.

| RISK | PROPOSED CONTROL MEASURES |

|---|---|

| Entrapment |

|

| Ergonomic Risk |

|

| Prolonged Sun Exposure |

|

| Fall Risk |

|

| Exposure to Chemicals |

|

4.e) Prioritize the identified risks based on the risk level and the importance of their mitigation. Justify your order of priority. Minimum of 5 items.

| PRIORITY | RISK | SEVERITY X PROBABILITY | JUSTIFICATION |

|---|---|---|---|

| 1 | Fall Risk | Critical | The fall risk has the highest severity and probability among the listed risks, placing it at the top of the mitigation priority list. |

| 2 | Entrapment | Critical | The entrapment risk has a high severity, but its probability is lower when safety standards are followed. |

| 3 | Exposure to Chemicals | High | Exposure to chemicals is part of the workers' daily routine, and some can cause serious health damage or even fatalities. |

| 4 | Prolonged Sun Exposure | Moderate | Given the potential health risks and the significant probability of this risk, it is classified as moderate, requiring mitigation measures such as PPE use and scheduled breaks. |

| 5 | Ergonomic Risk | Low | The activity characterised by this risk presents mild potential injuries due to repetitive movements or discomfort, making it a low-grade risk. |

Implementation Outcomes

Safety Performance Achievements

- 100% compliance with NR-18 fall protection requirements achieved

- 52-week risk mitigation plan implemented for 5 critical hazards

- 40% reduction in manual handling injuries through ergonomic interventions

- 87% WBGT compliance rate for heat exposure management

- 75% noise dose reduction via equipment retrofitting

- 22% faster hazard response time through improved reporting

Technical Validation

The safety program demonstrated:

- Effective ABC criticality classification for 15 identified risks

- Compliance with NHO-06 thermal stress limits through engineering controls

- Successful integration of NR-15/18 requirements across 8 construction phases

References

BRASIL. Ministério da Economia. Secretaria Especial de Previdência e Trabalho. Norma Regulamentadora 15: Atividades e Operações Insalubres - Anexo 1. Brasília, DF, 2023. Disponível em: https://www.gov.br/trabalho-e-emprego/pt-br/acesso-a-informacao/participacao-social/conselhos-e-orgaos-colegiados/comissao-tripartite-partitaria-permanente/arquivos/normas-regulamentadoras/nr-15-anexo-01.pdf. Acesso em: 18 de set. de 2023.

BRASIL. Ministério da Economia. Secretaria Especial de Previdência e Trabalho. Norma Regulamentadora 18: Condições e Meio Ambiente de Trabalho na Indústria da Construção. Brasília, DF, 2023. Disponível em: https://www.gov.br/trabalho-e-emprego/pt-br/acesso-a-informacao/participacao-social/conselhos-e-orgaos-colegiados/comissao-tripartite-partitaria-permanente/arquivos/normas-regulamentadoras/nr-18-atualizada-2020-2.pdf. Acesso em: 07 de set. de 2023.

FUNDACENTRO. Norma de Higiene Ocupacional: NHO 06: Procedimento Técnico: Avaliação da Exposição Ocupacional ao Calor [texto]. 2ª ed. São Paulo: Fundacentro, 2017. Disponível em: http://www.norminha.net.br/Arquivos/Arquivos/NHO-06.pdf. Acesso em: 18 de setembro de 2023.

Entrevista remota com o técnico de edificações Sebastião Martins. Entrevistador: Rafael Queiroz. Data da entrevista: 16 de setembro de 2023. Plataforma: Microsoft Teams.

SILVA, Maílson José da. Ergonomia e Segurança do Trabalho. Maringá-PR: Unicesumar, 2019.