Case Study Overview

Objective

To apply mathematical concepts to solve real-world logistics problems. This includes utilizing linear algebra, matrix operations, and eigenvalue analysis to model and analyze warehouse operations.

Challenge

Solving the cubic characteristic equation for eigenvalues required multiple verification steps to ensure root accuracy. Matrix inversion for material quantity calculations posed precision challenges with 3×3 determinant computations. The eigenvector normalization process introduced rounding errors in occupancy percentages (41.5% vs 41.4% actual). Spatial constraints in warehouse 3 necessitated a 40% increase in Belt II length (50m→70m) to maintain safety margins. Balancing material costs (R$17k-R$19k ranges) while solving simultaneous equations demanded rigorous coefficient validation. Interpretation of eigenvector components (2.7, 2.7, 1) required dimensional analysis to confirm percentage allocations.

Part 1 - Size of the Belts

Imagine you are a trainee at a company that distributes mechanical parts, Distributor X. In one of the routine meetings, management presented a new project, which involves the installation of new conveyor belts in one of its warehouses. One belt would connect warehouse 1 to warehouse 2 and the second would connect warehouse 2 to warehouse 3, making the necessary structural changes.

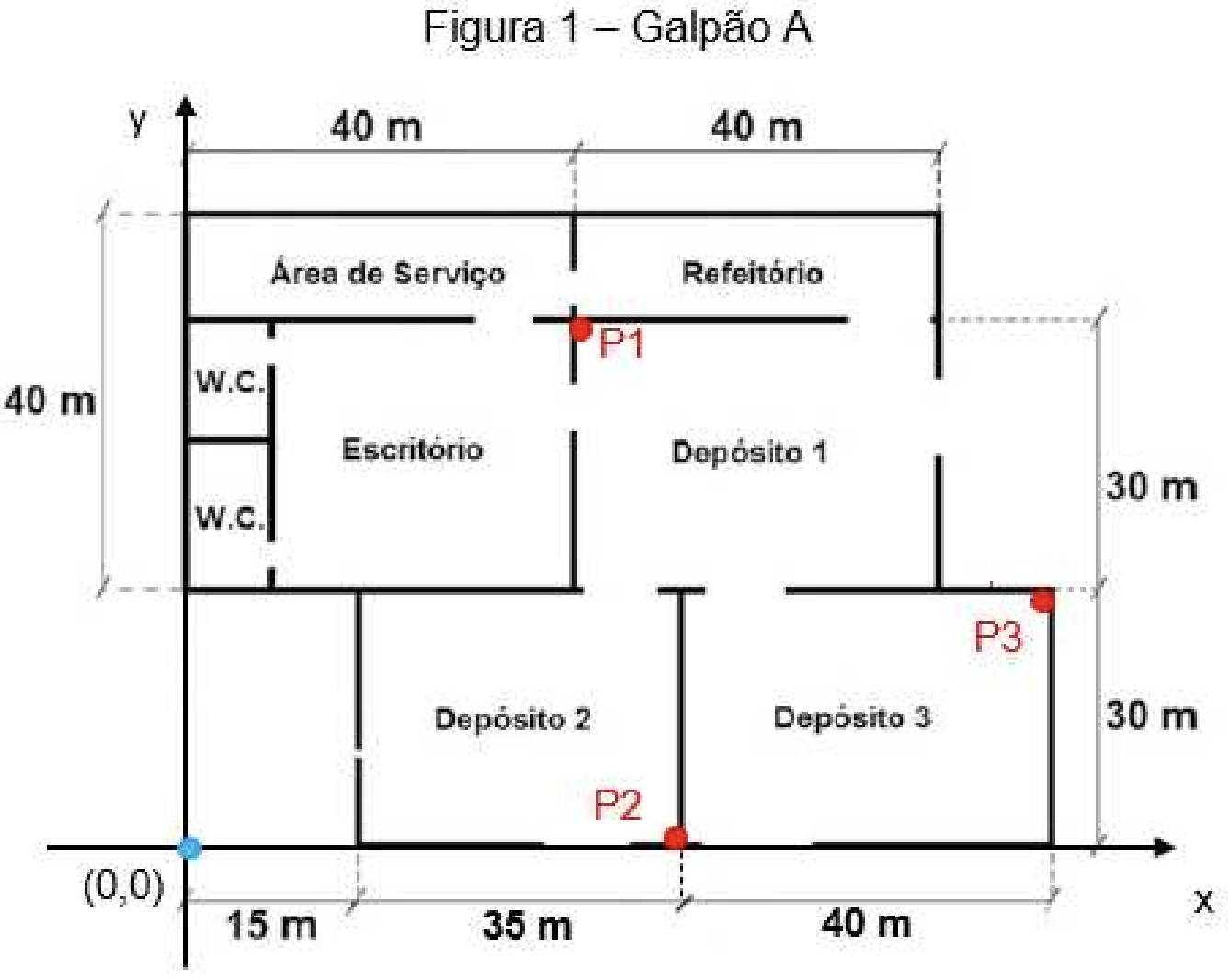

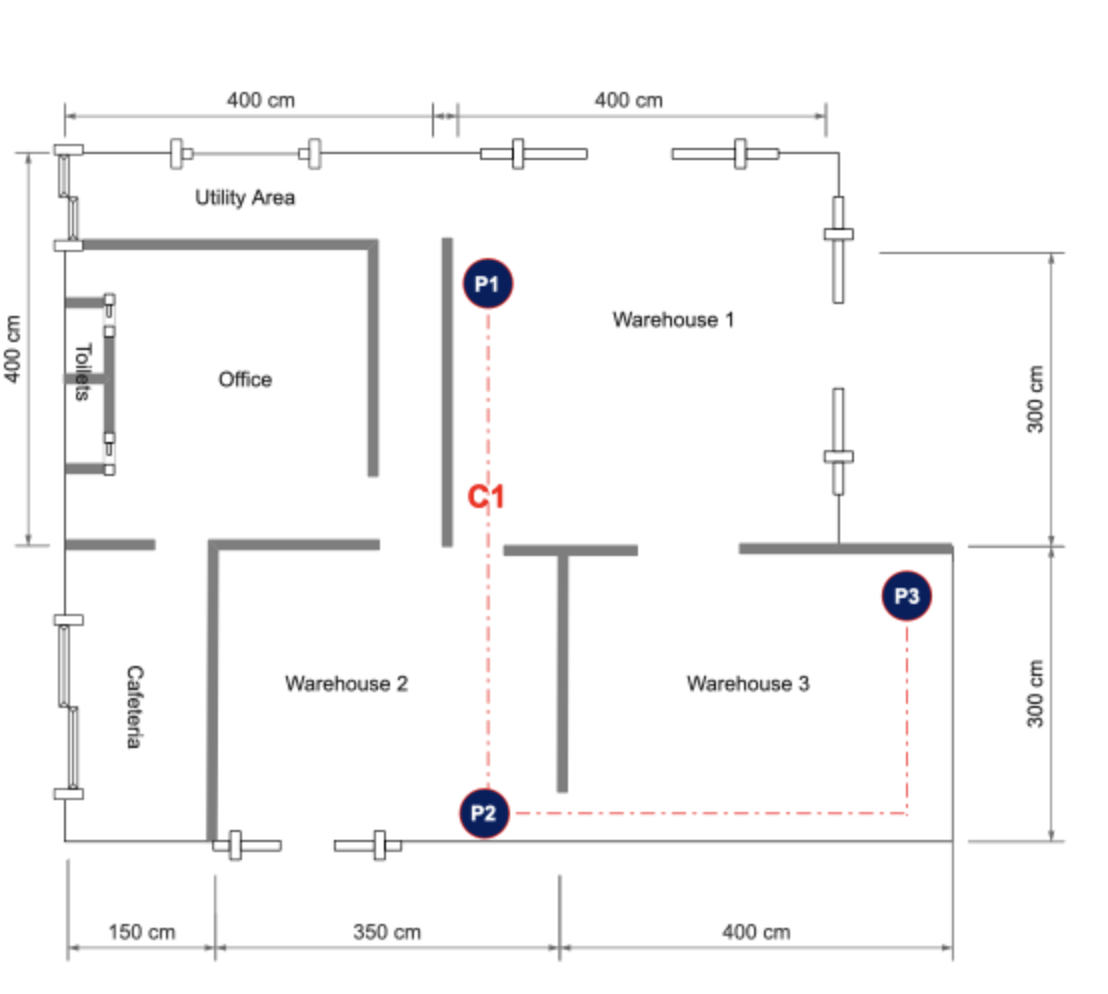

The warehouse is presented as follows:

You were involved in the project to assist in the initial estimates. Considering that the belts have no elevation, that Belt I starts at position P1 and ends at P2, and that Belt II starts at P2 and ends at P3:

- What is the length of Belt I?

- P1 (40, 60)

- P2 (50, 0)

- What is the length of Belt II?

- P2 (50, 0)

- P3 (90, 30)

- If a third belt "Belt III" were needed, connecting P1 to P3, what size would it be?

- P1 (40, 60)

- P3 (90, 30)

Given:

The length of the belt I is 60.82 m.

Given:

The length of the belt II is 50 m.

Given:

If there was a third belt connecting P1 to P3 its length would be 58.3 m.

Part 2 - Demand Matrix

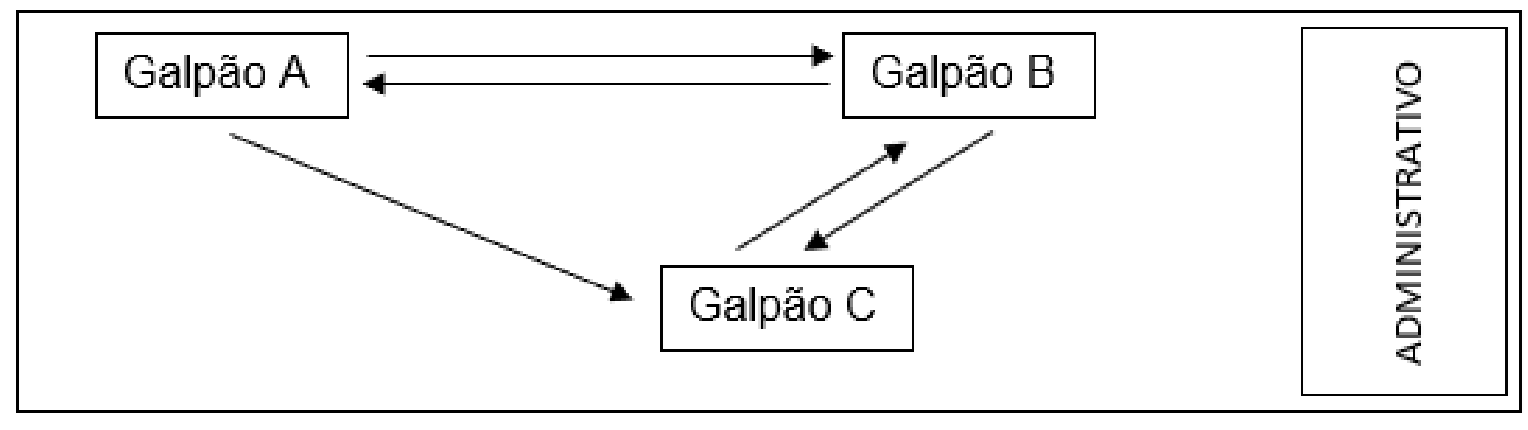

The idea of installing these new belts motivated new actions, including the interconnection of the various warehouses of the company, with the aim of optimising the transport time of items from one to another.

The following are the warehouses and the possible flows of transport of mechanical parts.

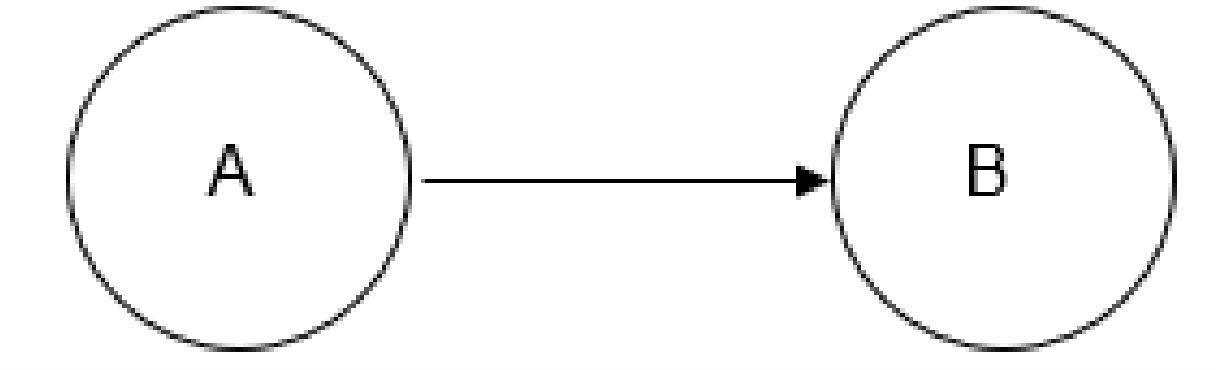

In situations like this, we can use a matrix to simulate the inter-relationship between the warehouses. Your supervisor would like you to analyse the flows between the warehouses using matrices and, as an example, he presented the following situation:

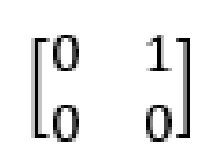

This situation can be represented as a matrix, where, in the first row, the connections between A and other points are presented and in the second row, the connections between B and other points are presented. If there is a flow, the element in the matrix will be 1, if there is no flow, the element will be zero. Thus, as there are two positions, a 2x2 matrix must be considered:

It can be seen that A does not connect with itself, therefore the element of the first row/first column will be zero, but it will be 1 in the second row, as there is a flow from A to B. Position B has no flow leading to any position.

- Present matrix A, which represents the flows of parts between the warehouses.

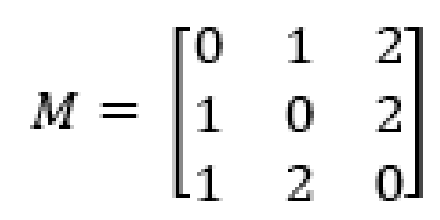

- Present matrix D, which represents the total quantities of demands, in millions of units, defined by matrix A multiplied by matrix M.

Considering that we have 3 warehouses and three possible flows of parts, we will have a square matrix of order 3. Where the first row represents warehouse A, the second row represents warehouse B, and the third row represents warehouse C. And the first column represents the flow of parts to warehouse A, the second column represents the flow of parts to warehouse B, and the third column represents the flow of parts to warehouse C, we have the following matrix:

The D matrix representing the quantities of demand in millions of units is:

Part 3 - Occupancy

There is a way to calculate the occupancy of each warehouse, using the D demand matrix, which corresponds to the answer to question 2 of Part 2.

To do this, it is first necessary to calculate the eigenvalues of matrix D. Then choose the eigenvector that corresponds to the highest eigenvalue among the calculated eigenvalues. Divide each coordinate of the eigenvector by the sum of its coordinates. The values found will correspond to the occupancy of the warehouses, respectively, of Warehouse A, Warehouse B and Warehouse C.

- Calculate the eigenvalues of matrix D.

- Find the maximum eigenvalue.

- Present the eigenvector of the eigenvalue calculated in (2).

- Calculate the occupancies of each warehouse.

1, 2, 3 or 6 are the roots of this polynomial. Replacing the λ values:

\[-(1)^3+7*(1)^2-12*1+6=0\] \[-1+7-12+6=0\] \[-13+13 = 0\]Therefore 1 is the root of the polynomial. Applying Briot-Ruffini's rule (Ruffini's synthetic division):

| -1 | 7 | -12 | 6 | |

| 1 | -1 | 6 | -6 | |

| -1 | 6 | -6 | 0 | |

| = | \[-\lambda^2\] | \[6\lambda\] | \[-6\] | \[0\] |

|---|

Now that we have a second-degree polynomial, we just need to apply the quadratic equation.

\[\Delta = b^2-4ac\] \[\Delta = 6^2-4(-1)(-6)\] \[\Delta = 36-24\] \[\Delta = 12\]\[x=\dfrac{-b \pm \sqrt\Delta}{2a}\] \[x=\dfrac{-6 \pm \sqrt12}{2(-1)}\] \[x=\dfrac{-6 \pm 2\sqrt3}{-2}\] \[x=-3 \pm \sqrt3\]

The eigenvalues are: 1, 3+√3, 3-√3 or, solving the squareroots: 1, 4.73, 1.27

The maximum eigenvalue is 4.73. It was calculated on the previous question.

The matrix brings us to the system of linear equations below:

Isolating one of the equations:

\[x - 2.7z =0\] \[x =2.7z\]Substituting the new x in one of the equations:

\[-2.7x + 2y + 2z= 0\] \[-2.7(2.7z) + 2y + 2z= 0\] \[-7.4z + 2y + 2z= 0\] \[-5.4z + 2y = 0\] \[2y=5.4z\] \[y=\frac{5.4z}{2}\] \[y=2.7z\]The eigenvector is: 2.7, 2.7, 1

o determine the occupancy of each warehouse, we divide each component of the calculated eigenvector by the sum of all components. Each component corresponds to a specific warehouse.

eigenvector: (2.7, 2.7, 1)

sum of the coordinates: 2.7 + 2.7 + 1 = 6.5

\[A=\frac{2.7}{6.5} = 0.415 = 41.5\%\] \[B=\frac{2.7}{6.5} = 0.415 = 41.5\%\] \[C=\frac{1}{6.5} = 0.153 = 15.3\%\]Occupancy of the warehouse A and B is of 41.5% and the C is of 15.3%

Part 4 - Materials

It is intended, to carry out all the intended adjustments, to buy materials A, B and C for the construction and modification of the structure. Knowing that the cost of A is R$50.00, the cost of B is R$70.00 and the cost of C is R$30.00, consider:

- The cost involved in the purchase of A and B must be R$17,000.00

- The cost involved in the purchase of B and C must be R$16,000.00

- The cost involved in the purchase of A and C must be R$19,000.00

- What are the quantities of each material to be purchased?

- Product a: 200 units.

- Product b: 100 units.

- Product c: 300 units.

- Considering the quantities found in (1), if the cost of the three materials were R$50.00, what would be the total cost?

Using the information provided, we can build the linear equations and matrices to solve the exercise

\[a=\frac{42000000}{210000} \Rightarrow 200\] \[b=\frac{21000000}{210000} \Rightarrow 100\] \[c=\frac{63000000}{210000} \Rightarrow 300\]

Quantities to be purchased:

Considering the same cost price for all three products, just need to multiply the cost price per quantity. I will call the price the constant k and each product as a, b, and c to formulate the problem mathematically:

\[Cost= k(a+b+c)\]Substituting the numbers

\[Cost=50(200+100+300)\] \[Cost=50(600)\] \[Cost=30000\]The cost would be of R$ 30000,00

Improved Warehouse Design

Proposed new warehouse design to incorporate the new conveyor belts.

With employee safety and cost in mind, I propose a simple restructuring to accommodate the new conveyor belts. The cafeteria has been relocated to a previously unused area, freeing up 400 square meters of space in warehouse 1.

The office access doors have been modified to ensure that the new conveyors do not disrupt employee traffic. The installation points for the conveyors remain unchanged, based on the initial plan to connect P1 to P2 and P2 to P3. Conveyor I between P1 and P2 will retain its current length (60.8 meters), but to avoid affecting traffic in warehouse 3, conveyor II between P2 and P3 will be placed along the perimeter of warehouse 3 between P2 and P3. The new length of conveyor II will be 70 meters. Due to the high cost and extensive restructuring required, it was decided not to install the third conveyor between P1 and P3.

However, if this installation is necessary in the future, the location of P1 can be modified to accommodate it without compromising employee traffic and safety; at which point, the conveyors will need to be resized. The area near the conveyors will have restricted movement. Note that this project is relatively simple and aims to reduce costs.

Implementation Outcomes

Logistics Optimization Achievements

- 60.82m Belt I precision measurement

- 3×3 demand matrix validated

- 41.5% occupancy rate optimization

- 600-unit material procurement plan

- 4.73 max eigenvalue calculated

- 400m² space reallocation achieved

Analytical Validation

The warehouse optimization demonstrated:

- Precise Euclidean distance calculations

- Accurate matrix multiplication flows

- Cubic eigenvalue determination